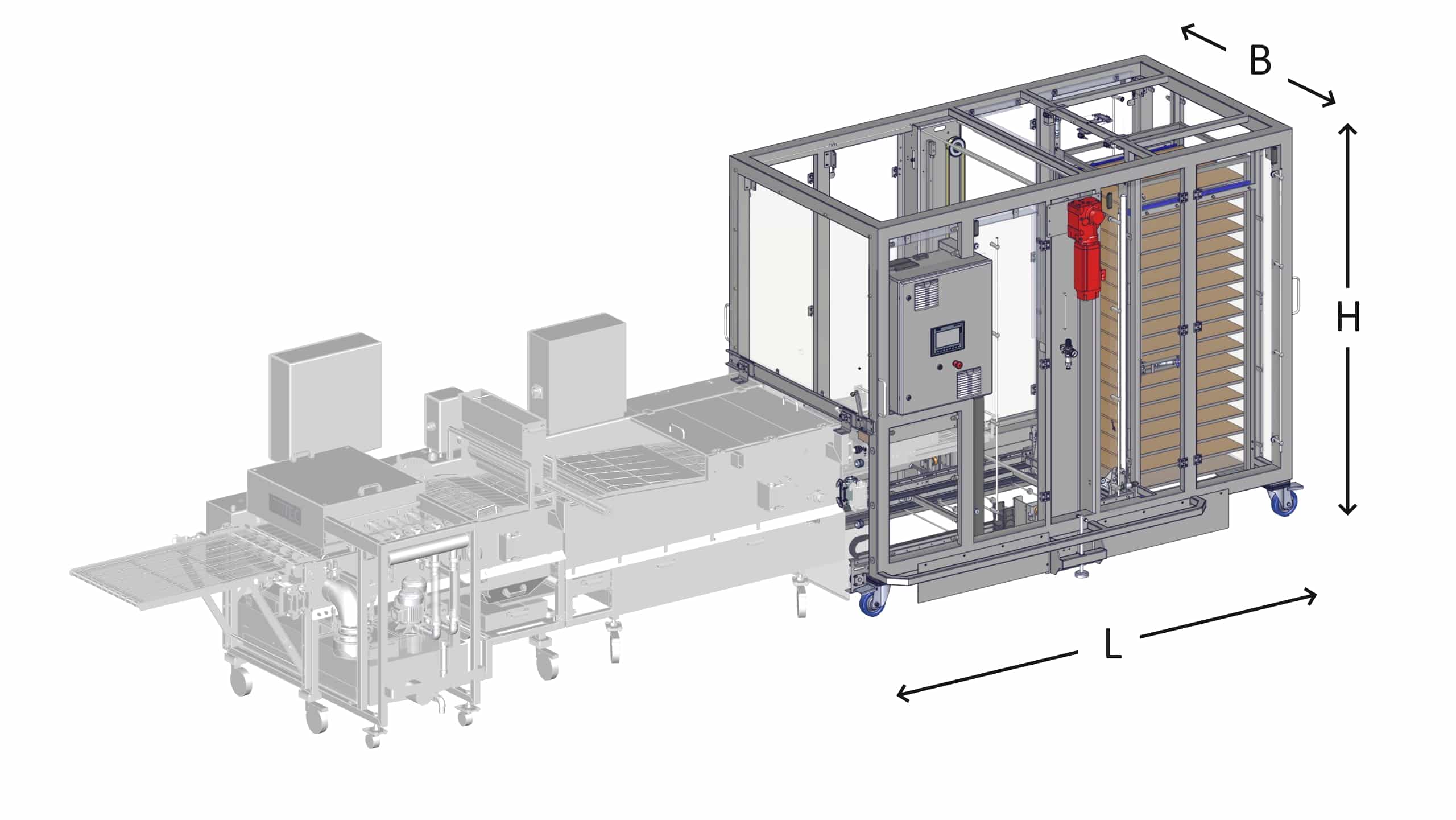

The rack with empty peelboards or trays is simply placed in the docking station. The integrated lifting and transport system then takes over. It removes the individual peelboards or trays and transports them under the panner of the lye unit. After the lye-treated products have been panned, the peelboards or trays are returned to the rack. The process starts again until the rack is filled and replaced.

Between the lye unit and the rack loader, the option of manual or automatic cutting of the pretzels is often chosen.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.