The automatic dough feed to the head machine is in any case a great labor-saver and saves time-consuming and strenuous manual work.

If dough rests in the kettle, for example, the portion-wise feeding into the dough band former ensures a more uniform dough band and thus higher weight and shape accuracy of the dough pieces, especially with particularly soft doughs.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

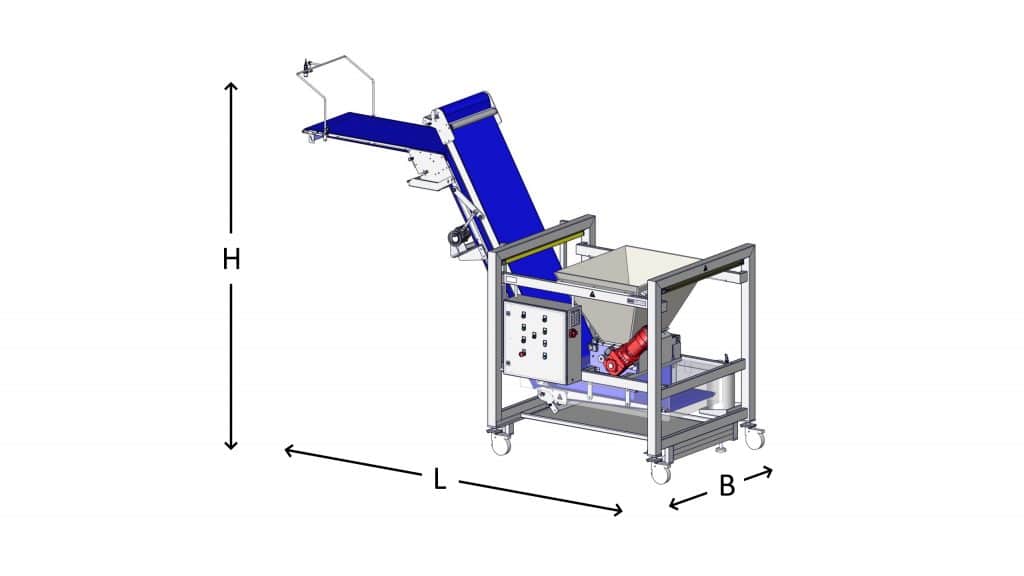

The hopper of the pre-portioner can hold the complete kettle filling, so that the emptied kettle is immediately available for further use. A filling level sensor on the bmTEC pre-portioner measures the filling level in the hopper of the head machine and portions the dough accordingly. Via an adjustable ascending belt, the dough portions are then fed to the head machine as required and continuous operation is ensured.