Automatic dough feeding to the head machine in defined portions is in any case a great labor-saver and saves time-consuming and strenuous manual work. In certain cases, it is also a significant factor for the subsequent quality of the product.

If, for example, dough rests in the kettle, portionwise feeding into the dough band former ensures a more uniform dough band and thus higher weight and shape accuracy of the dough pieces, especially in the case of particularly soft doughs.

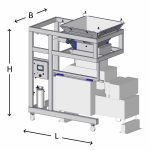

The hopper of the pre-portioner can hold the complete kettle filling, so that the emptied kettle is immediately available for further use. A filling level sensor on the bmTEC pre-portioner measures the filling level in the hopper of the head machine. The dough is portioned into the hopper on demand and continuous operation of the head machine is ensured.