It can be a real challenge for the operator to feed the trays onto the panner at the required speed and to remove them again after panning. It is not uncommon for the performance of the entire line to have to be reduced or for an additional employee to be assigned to the panner.

With our automatic feeding of trays from the tray-wagon to the panner, you can significantly increase the transfer speed at the panner without having to deploy additional personnel.

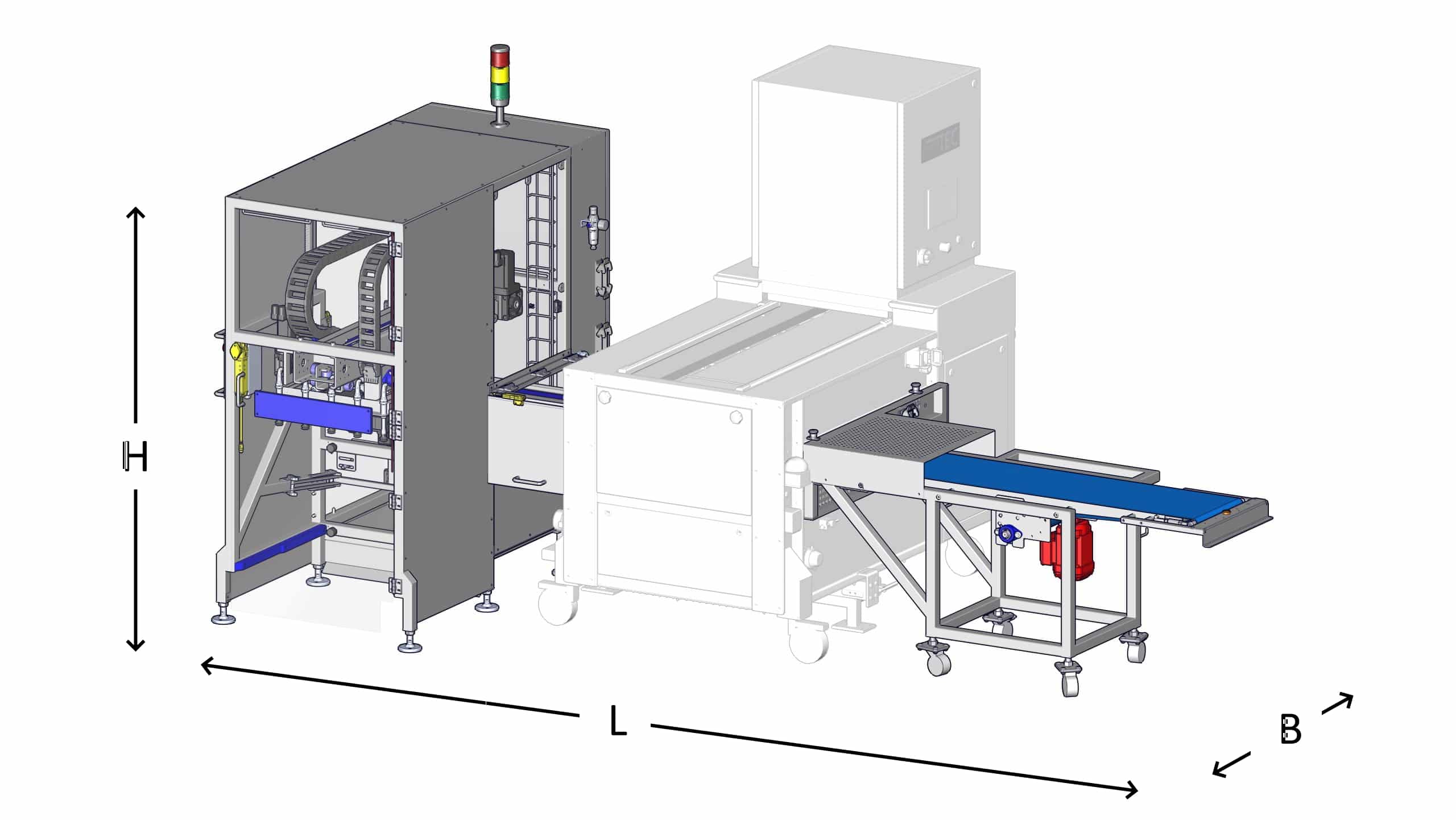

Your employee simply pushes the tray-wagon into one of the two docking stations. The built-in vacuum lifting and transport system picks up the trays one by one and positions them on the positioning belt. This conveys the trays precisely under the panner and, after loading, further on to the operator side of the panner for manual removal, where there is space for up to 2 trays as standard – but more can be accommodated on request, up to and including automated tray handling after the panner (see product “Tray handling after panner”).