A well-known bottleneck in line performance is often found in the area of panning. While your panner, at least if it was built by bmTEC, could technically still pann very precisely much faster, your employee simply does not manage to insert and remove the trays at the permanently required speed.

With the tray destacker and the tray feeder to the panner, you significantly increase the convertible speed at the panner without having to deploy additional personnel.

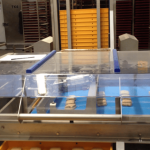

Your employee simply places the stacked trays on the input position. The stack is then held by the machine and the lowest tray is placed on the positioning belt. This conveys the tray precisely under the panner and, after loading, continues to the operator side of the panner for manual removal, where there is space for up to 2 trays as standard – but more can be accommodated on request.

The use of metal trays also remains possible within this system. The trays can be placed manually on the positioning belt between the destacking magazine and the panner. This precisely conveys each tray under the pannerand, after loading, continues to the operator side of the panner for manual removal.