High-quality, well seeded bakery products, where the seeds remains on the product and not in the bag, this is what seeding units from bmTEC stand for.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

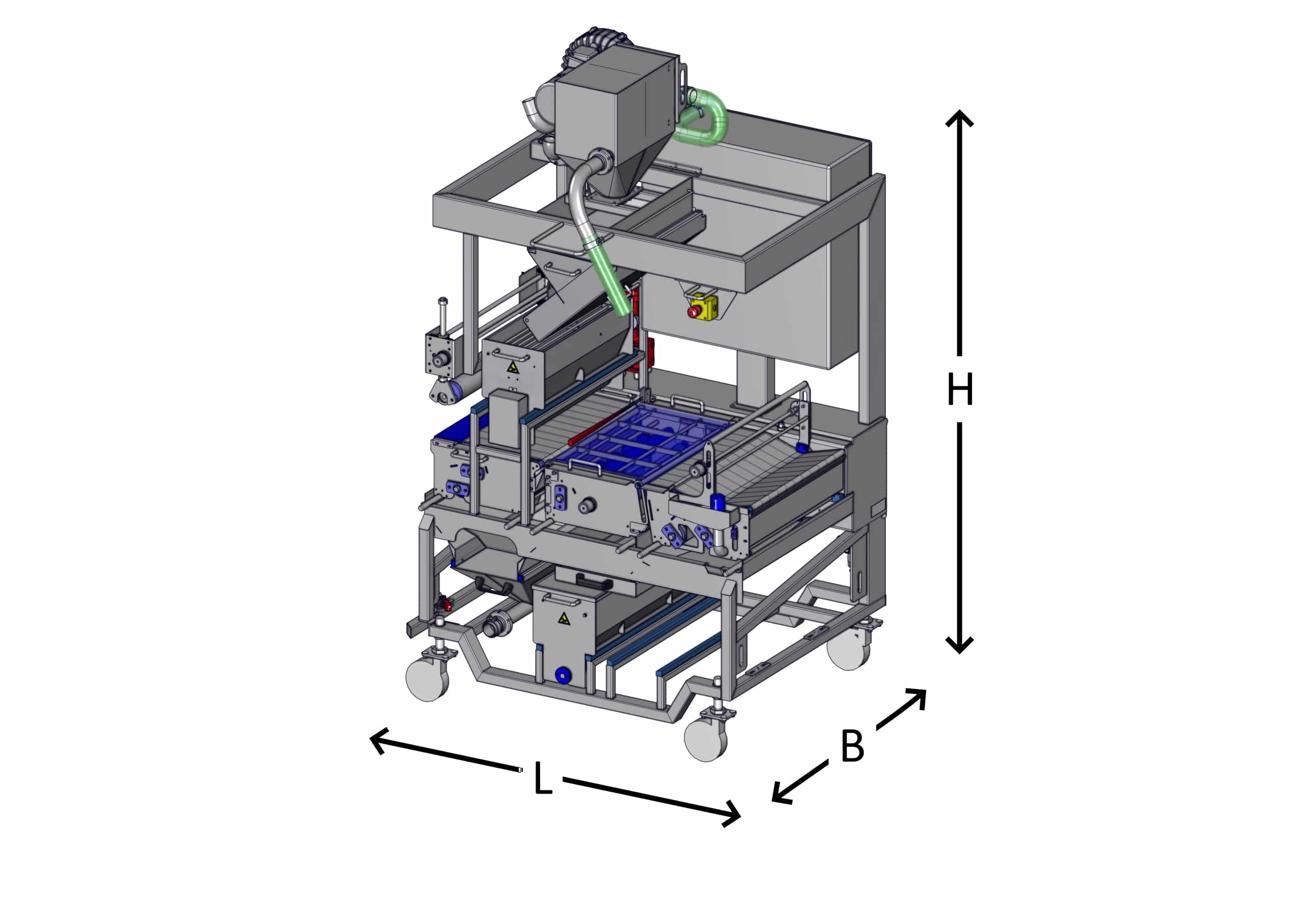

In the water bath, the product is moistened on the underside and turned on the subsequent tilting belt so that the moist side is on top. On the seeding belt, the seeds fall onto the product from above and can be pressed down with the pressure roller. For products seeded on both sides, the whole process is repeated. In this way, a wide variety of products can be seeded on one or both sides, even in large quantities and at high speeds, with all common seeds and seed mixtures. At the same time, the proven design reliably prevents unwanted carryover of moisture and seed into the line.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Like all our line modules, the seeding unit is mobile and easily integrated into the entire system by means of a quick-locking and locking system.